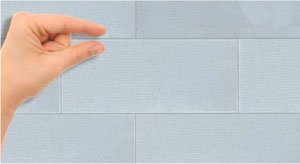

UltraTech FixoBlockis a versatile thin jointing material for laying AAC blocks, fly ash bricks, concrete blocks etc. The product is specially designed to provide higher bonding as a result of higher tensile adhesion strength. UltraTech FIXOBLOCK is pre-mixed, easy to apply high quality mortar comprising of cement, graded sand and admixtures. FIXOBLOCK replaces conventional jointing mortar of 12-18mm thickness with highly versatile 3-5mm thickness.

UltraTech FixoBlock helps to speed up the build process and achieve the required insulation performance of AAC Blocks for the buildings. UltraTech FIXOBLOCK (Thin joint masonry) is a fast, clean, accurate system for construction using autoclaved aerated concrete blocks of close dimensional tolerance with 2mm-3mm mortar joints.

Technical Specification

| Parameter | UltraTech FIXOBLOCK |

| Appearance | Free Flowing Powser |

| Colour | Gray |

| Water Demand# | 25-30% |

| Workability | Very Good |

| Hard Dry# | 24 hrs. |

| Pot Life | Approximately 2 hrs @ 27 C |

| Self Curing | Yes, No additional water curing is required |

| Tensile adhesion strenght @28 days | 8 N/Sq.mm |

Features and Benefits

»

Thin jointing material with very high adhesion strength

»

Pre-mixed and ready-to-use. Only water is to be mixed at site

»

Economical. Eliminates lengthy and cumbersome processes of site mixing, thus transport and storage of all individual materials is avoided

»

Ease of mix and much faster application

»

Thin layer application results in structure being compact

»

No water curing is required after application

»

Minimizes the undulation of the surface

»

Being a thin layer, chances of water percolation is negligible

»

Being premixed, it saves considerable time and labour

»

Being premixed, it saves considerable time and labour

»

Eco-friendly product

»

Raw materials are processed, reducing the chances of efflorescence